the industry

transformation

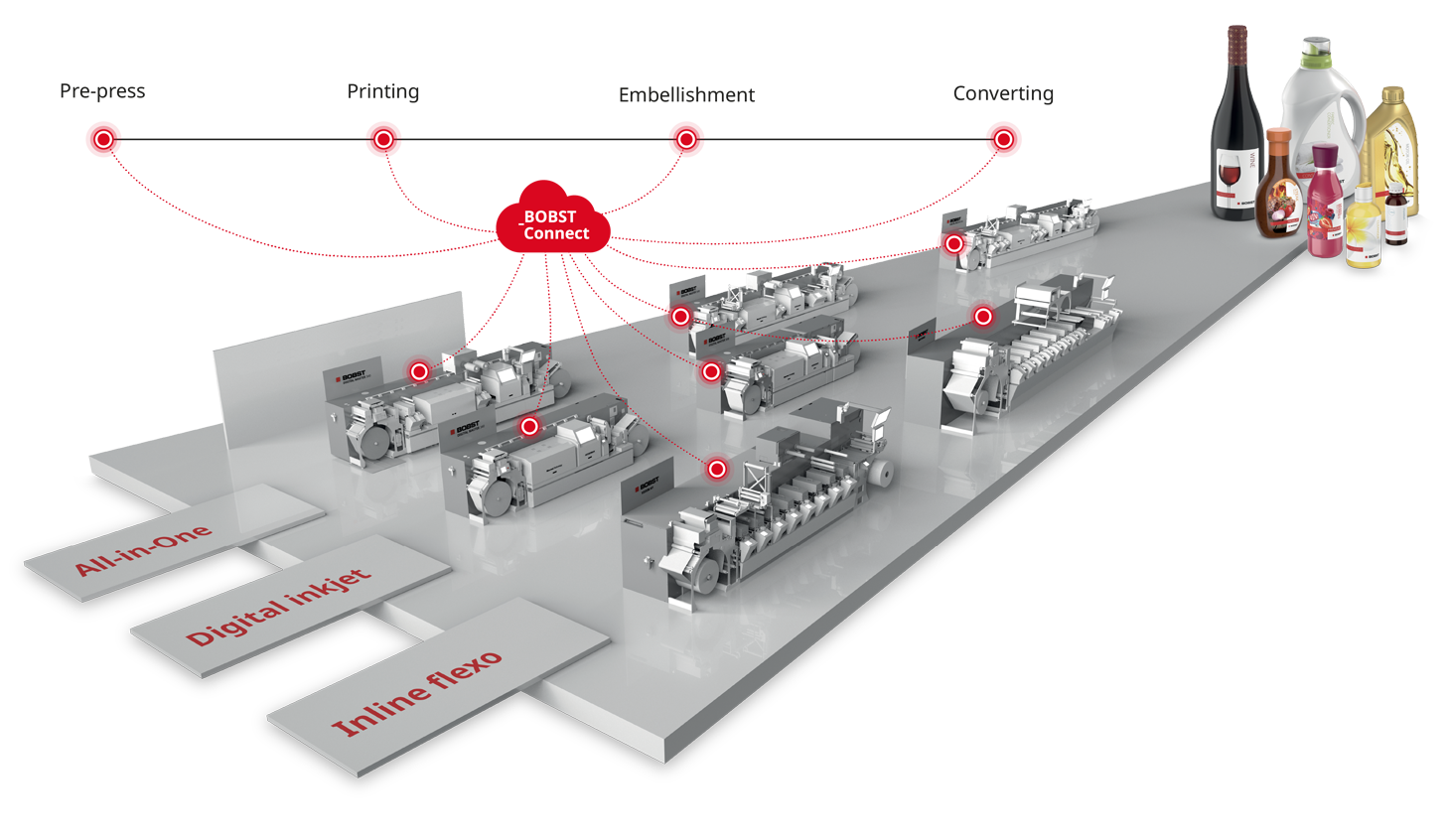

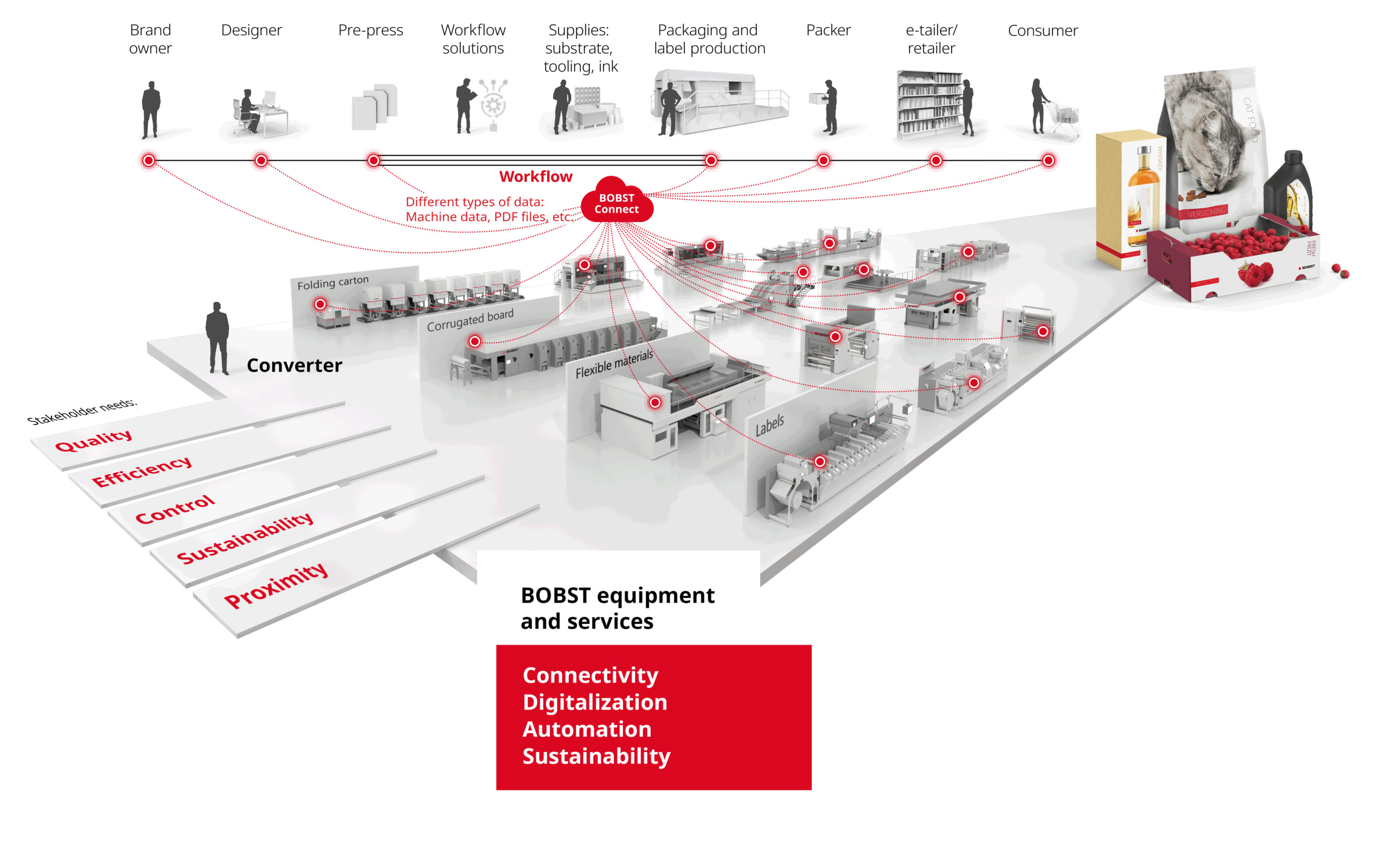

Our vision for the packaging industry is a fully connected, digitalized, automated packaging world – contributing to sustainability worldwide.

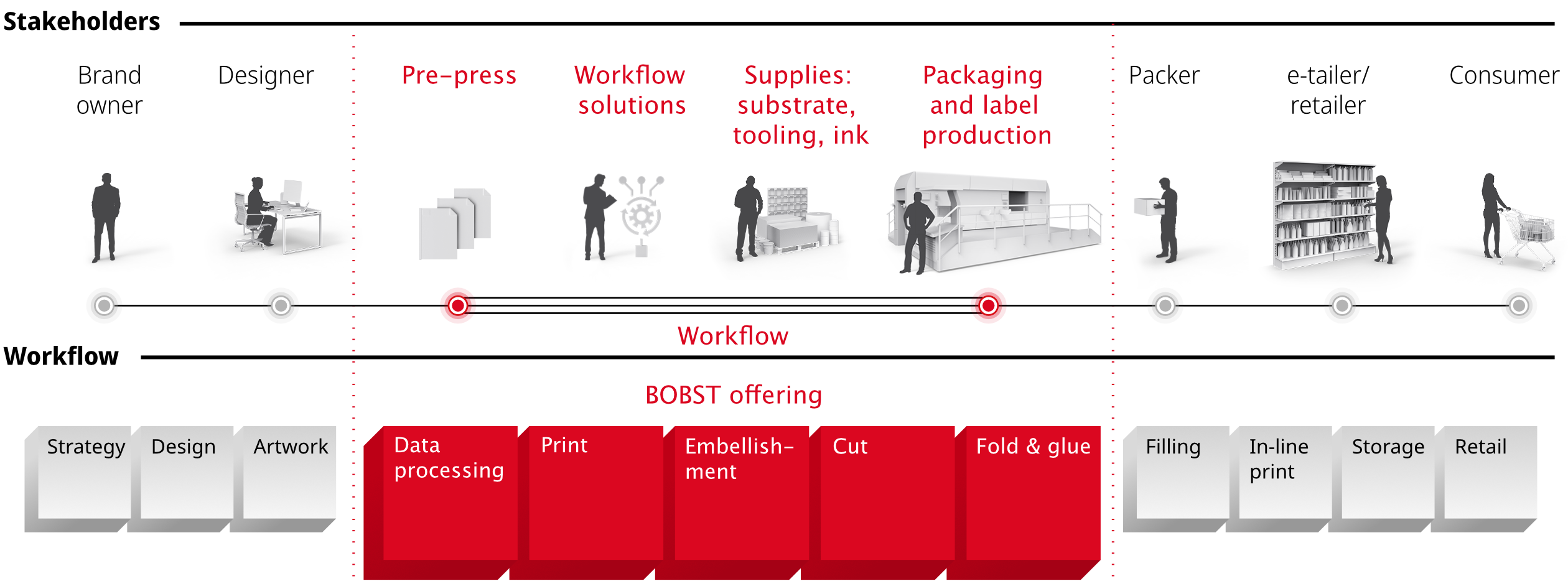

As one of the technology leaders, we actively drive the industry transformation: from mechanical to digital, and from manufacturing machines to process solutions along the entire workflow.

At the core of our vision:

BOBST Connect

The progress towards our vision offers a steady transformation for the packaging industry.

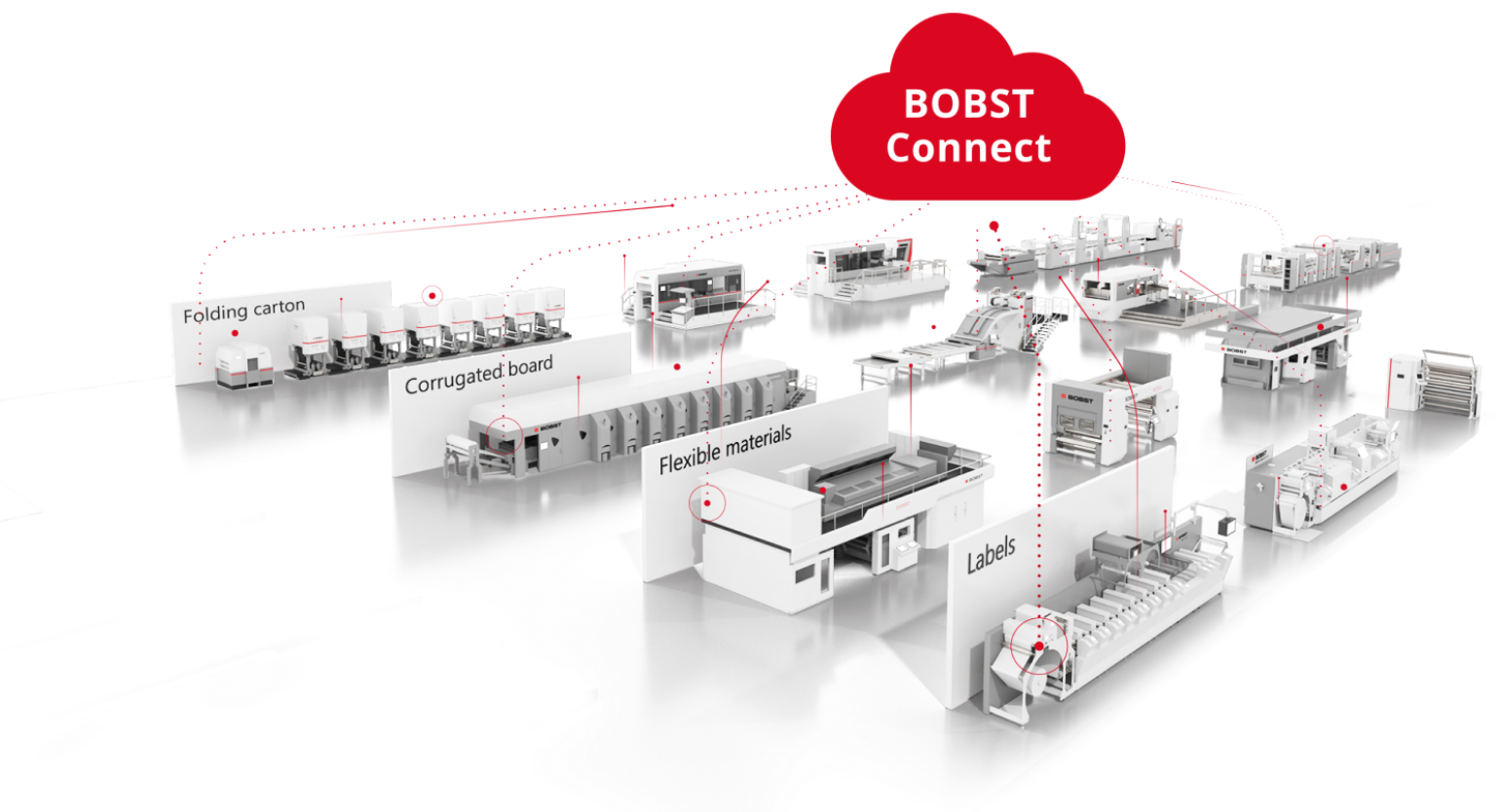

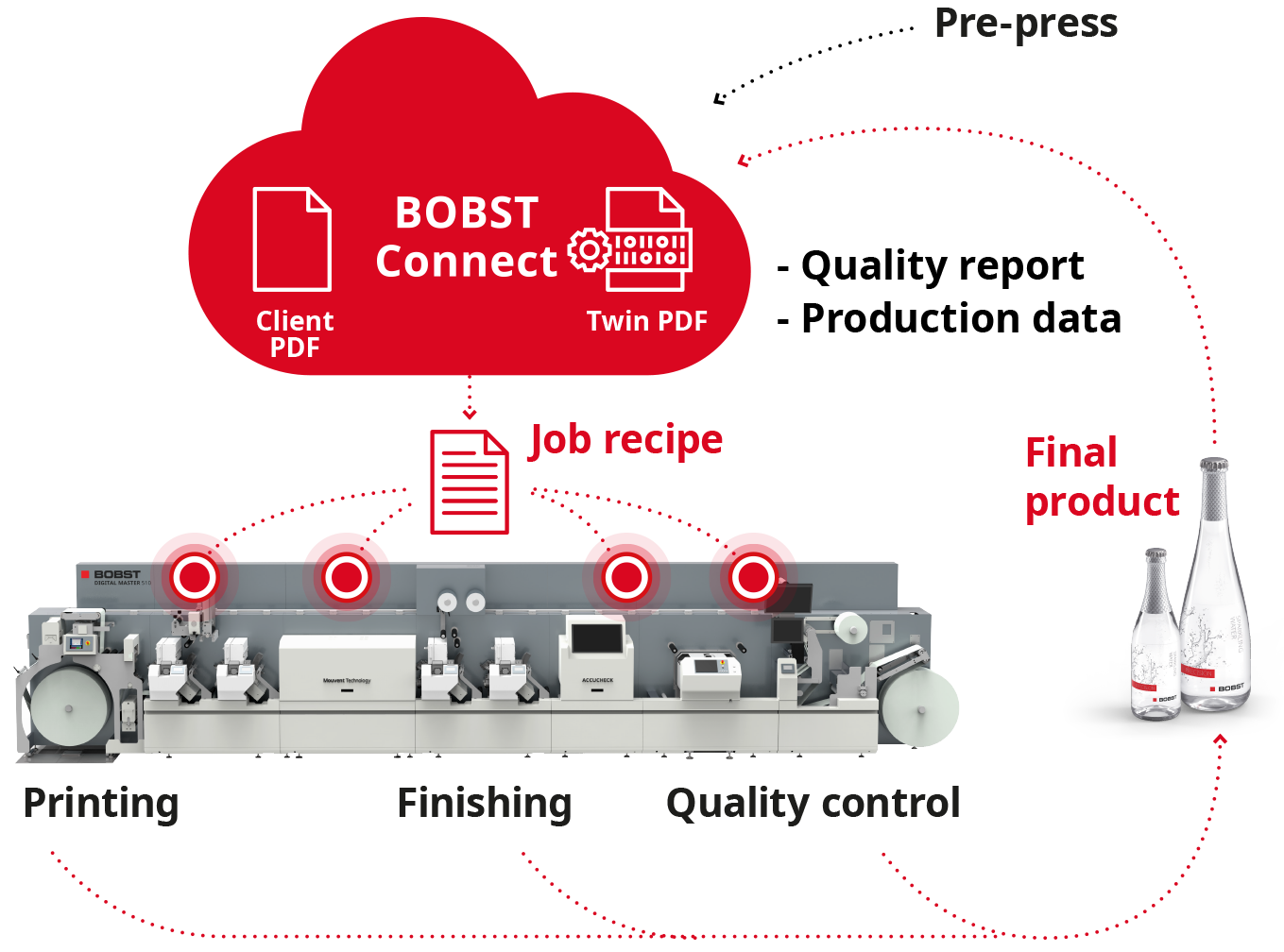

At the heart of this transformation is BOBST Connect, our constantly evolving, cloud-based digital platform that enhances and improves packaging productivity.

BOBST Connect brings data and digital services together in one fully connected platform, with BOBST machine insights and expertise built-in, enabling overview and orchestration of the production process. Along with its connectivity, BOBST Connect provides optimization.

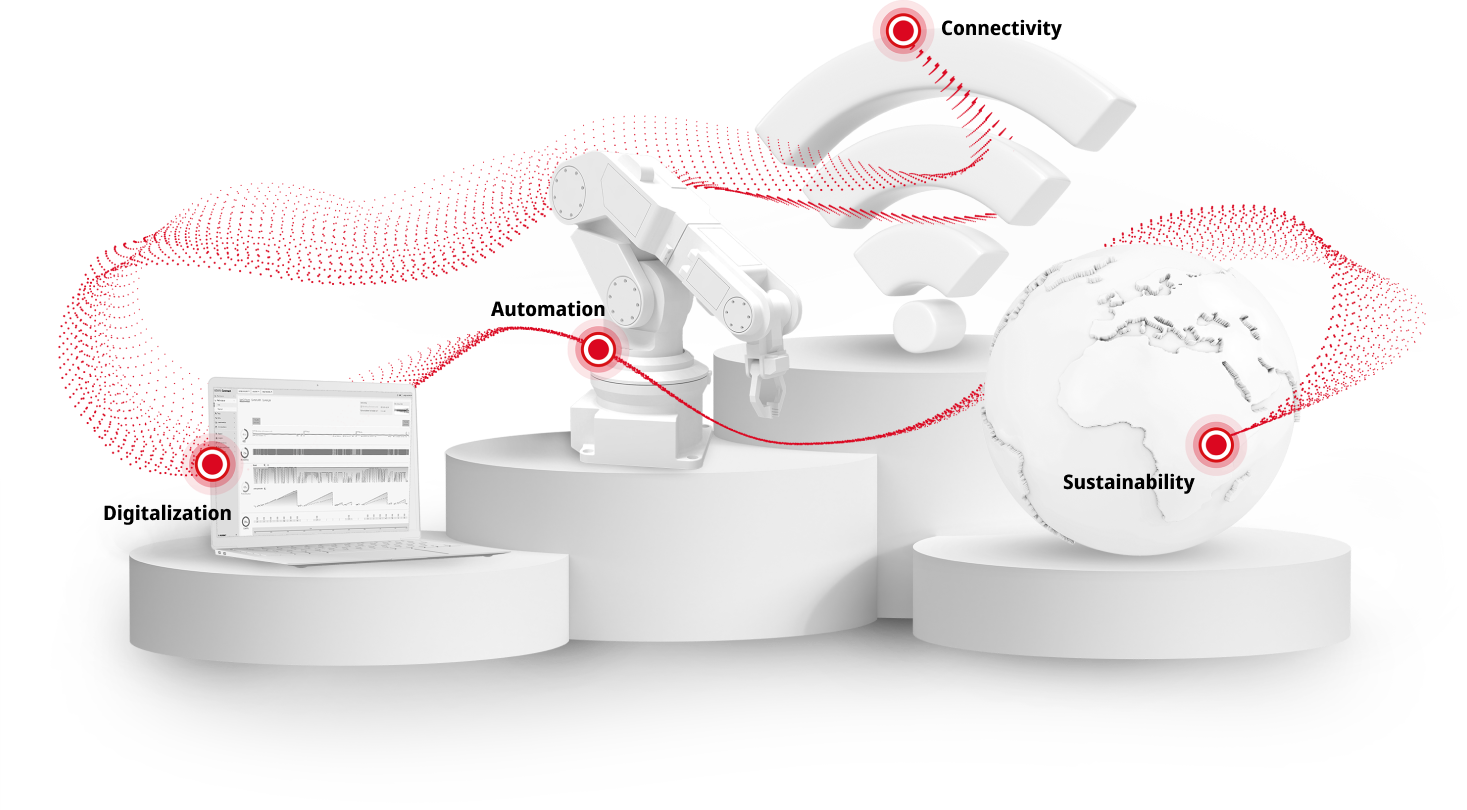

The four pillars of our industry vision are the cornerstone of the industry transformation.

BOBST is changing the way packaging is produced: Data and digital services all together in a fully connected platform, enabling complete oversight and orchestration of the production.

Connectivity

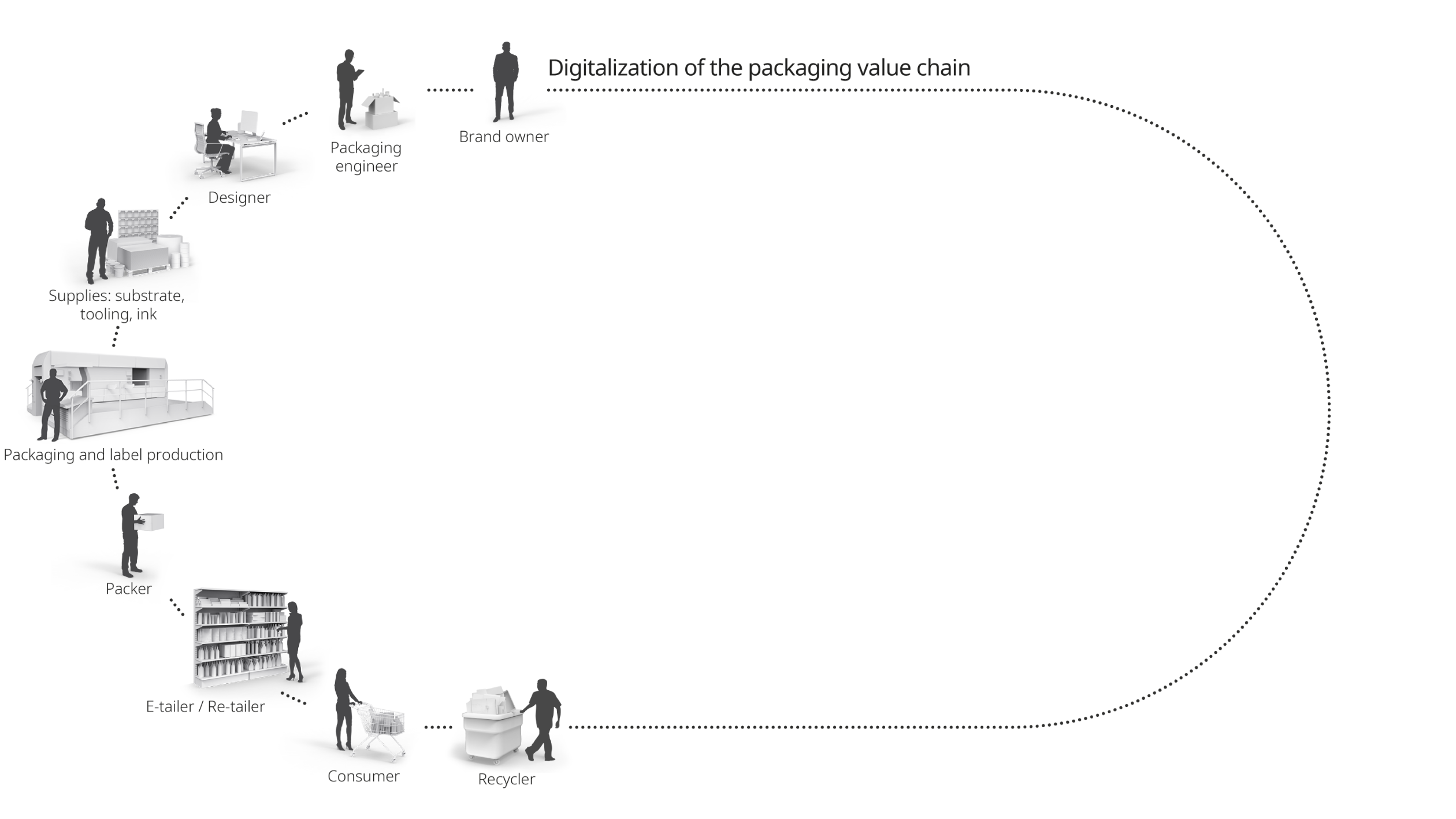

BOBST is driving connectivity: in a fully connected packaging production, all machines, tooling and systems will “talk” to each other. Stakeholders can access and share data, through a cloud-based platform.

Digitalization & automation

Through digitalization and automation, BOBST is changing the way packaging is produced. End-to-end digitalized solutions are being developed offering a seamless quality of production to converters, enabling more productivity, reducing waste and an ever-increasing quality.

Sustainability

Through its sustainability strategy under three work streams – operations, equipment, and packaging use & end-of-life – BOBST is committed to make progress with relevant business indicators and build important partnerships.

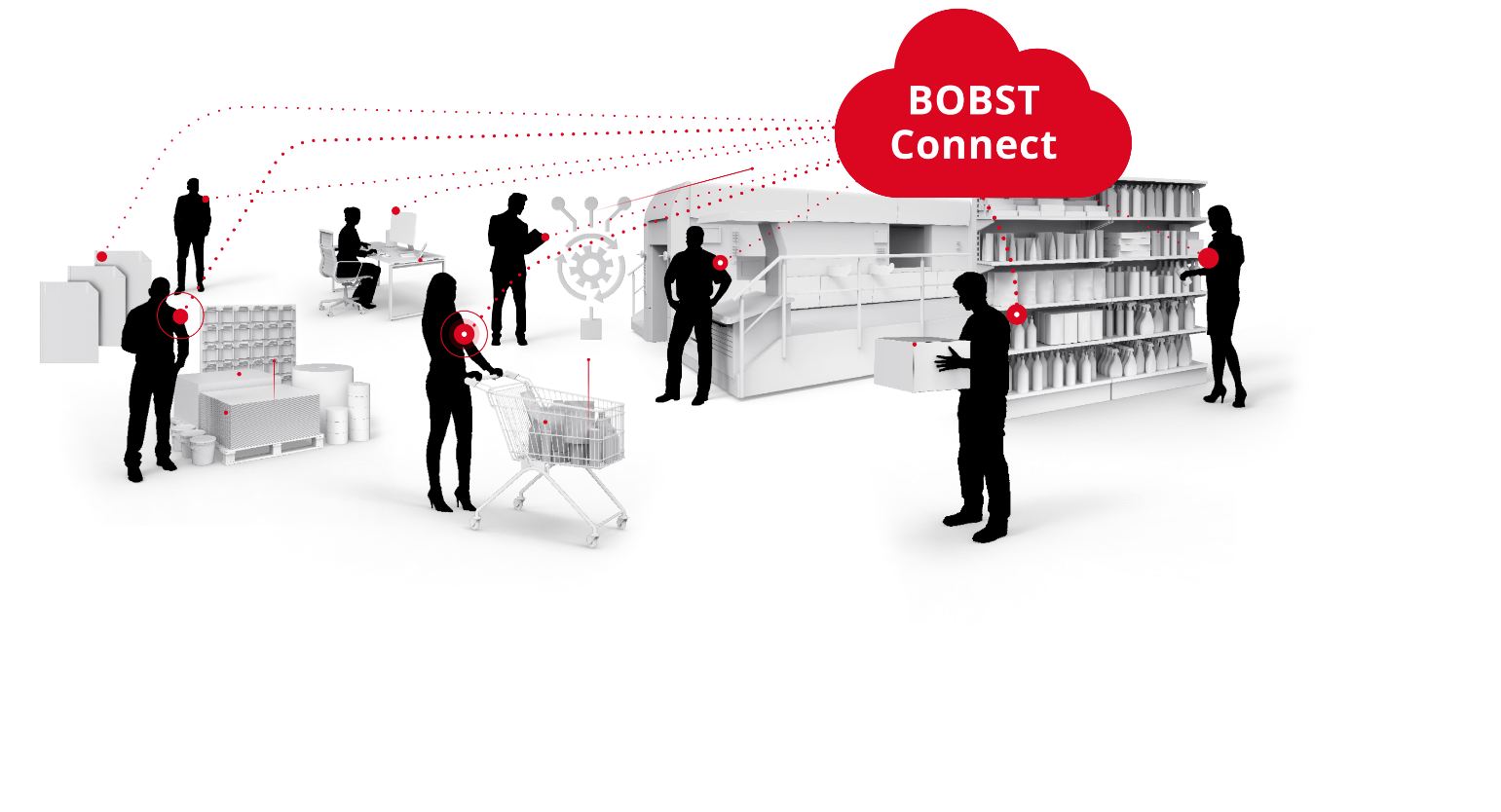

Value creation from brand

owner to consumer

Converters of every size are under increasing pressure to deliver the ideal packaging and labels with smaller lead times, shorter runs, mass customization, while ensuring zero-fault production and supporting new business models (such as e-commerce).

BOBST understands that these new challenges are an opportunity to not only offer quicker and more reliable equipment, but to integrate the equipment into the workflow to leverage the value of data fully.

Translating the industry vision into reality

BOBST Application management is the driver of making the BOBST industry vision a reality – contributing to the positioning of BOBST as innovation industry leader. The innovative consulting service has been designed for the needs of converters and brand owners, providing guidance on technologies, raw materials, processes and business cases along the entire packaging value chain.

Benefits of the

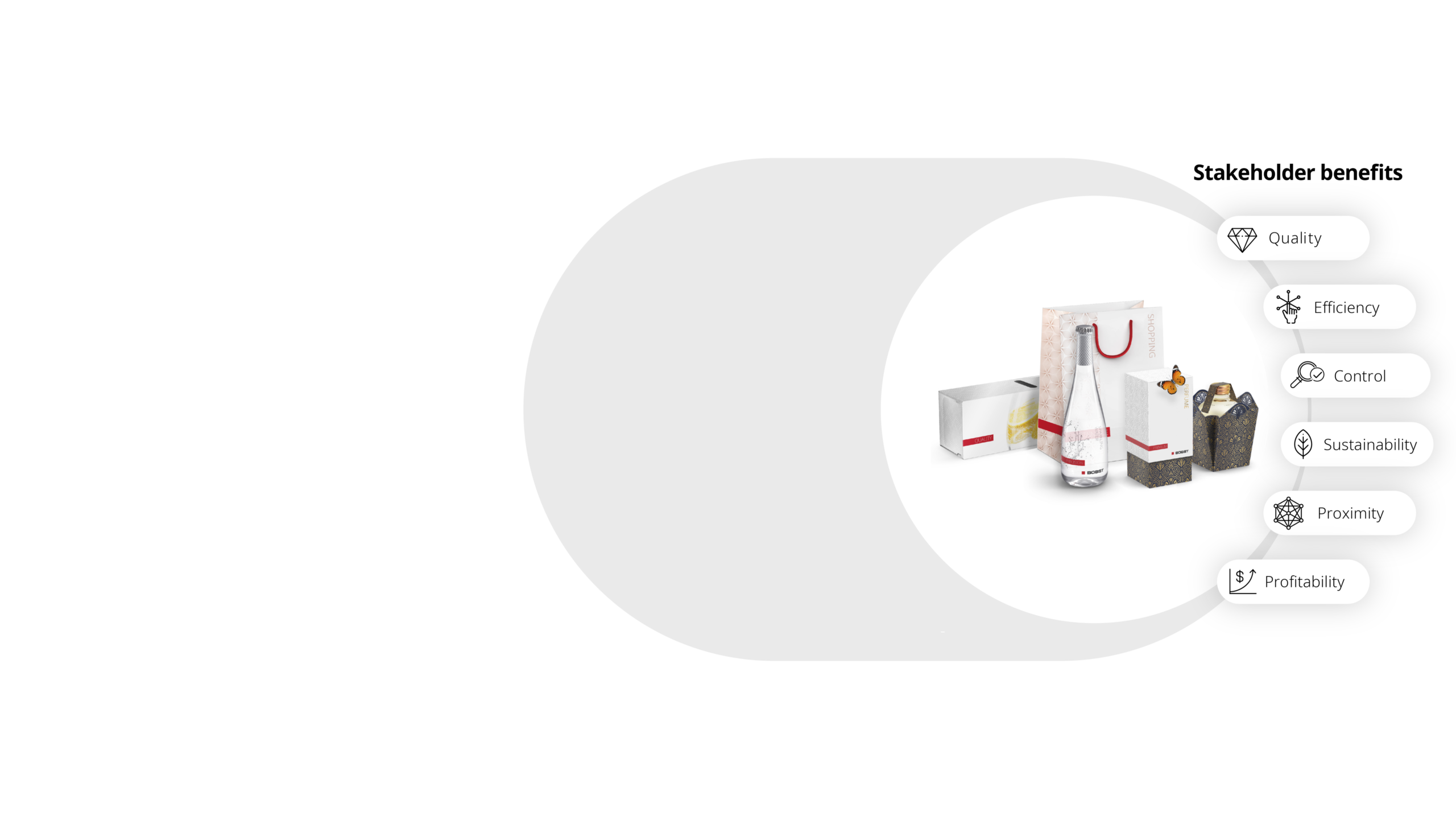

BOBST industry vision

Converters and brand owners benefit from professional insights on market opportunities, on state-of-the-art solutions, and on next levels of technology development.

Our specialized end-to-end know-how regarding each step of packaging production adds value to the machines, services and other devices offered by BOBST.

From an innovation perspective, the systematic expertise of Application management ensures that BOBST will have the right solution at the right time, for different industries.

Sustainable packaging solutions

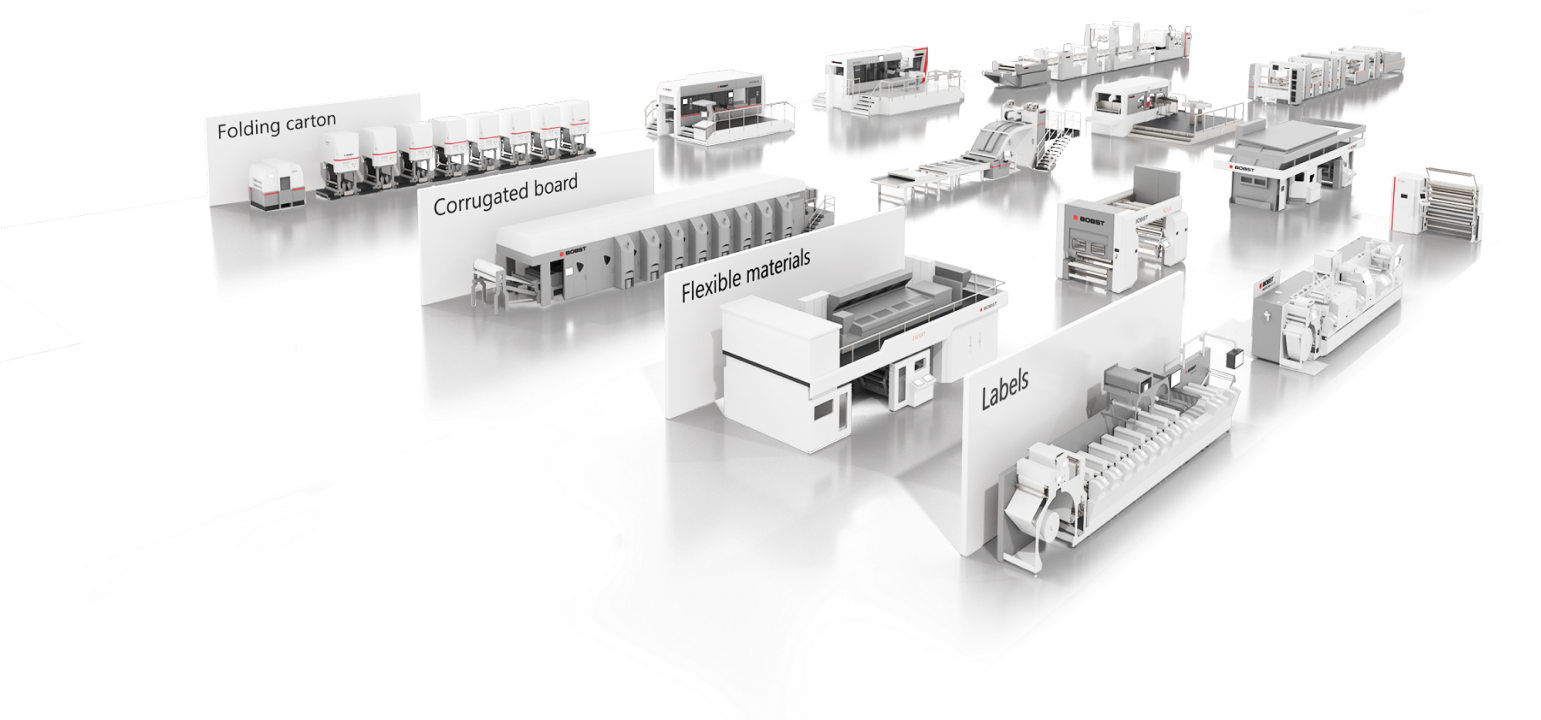

BOBST serves four industries with innovative and sustainable packaging and label solutions:

Corrugated board

Flexible packaging

Folding carton

Labels

More information about our packaging solutions:

Leading

innovation

What BOBST can do for you,

today and in the future

BOBST has the recipe for your success; we ensure an efficient dataflow between the physical and the digital world, with an automated and digitalized production flow, orchestrated by BOBST Connect.

Services and performance

Powering performance with expertise and digitalization

Solutions to enable efficient data flow between pre-press and physical equipment are set to leverage digital information, improve make-ready times, and automate jobs’ preparation.

Solutions to access the most accurate and actionable data from a job running on a BOBST machine, as well as to improve efficiency, control, and data knowledge.

Solutions providing a full range of remote assistance services to solve the vast majority of problems directly online and with the support of BOBST experts.

Solutions for accessing all relevant spare parts, consumables and useful documentation. Based on BOBST machine monitoring data, the right maintenance decisions can be made at the right time.

Solutions to fully optimize production and overall equipment efficiency and leverage factual data-driven insights.

Prepare

jobs with agility

Produce

more efficiently

React

to unexpected events

Maintain

your investment

Optimize

productivity

Job & recipe management

Job & recipe management  Equipment

monitoring

Equipment

monitoring  Quality

management

Quality

management  MyBOBST

MyBOBST  Helpline

Helpline  Equipment

monitoring

Equipment

monitoring  Quality

management

Quality

management  Performance management

Performance management  Certified die-makers

Certified die-makers  TooLink

TooLink  High performance tooling

High performance tooling  TooLink tool

manager

TooLink tool

manager  Digital inspection table

Digital inspection table  Consumables

Consumables  Spare parts

Spare parts  Lifecycle

management

Lifecycle

management  Wear parts

Wear parts  Upgrades

Upgrades  Training

Training  On-site repairs

On-site repairs  Preventive

maintenance

Preventive

maintenance  Process optimization

Process optimization  Relocation

Relocation  Machine remanufacturing

Machine remanufacturing BOBST Connect is our cloud-based digital platform, which improves productivity.

It ensures an efficient dataflow between physical and digital world with an automated & digitalized production flow.

It is a one-stop shop for increasing productivity capability at every stage.

It will serve our customers most effectively today and into the future, around the workflow optimization.

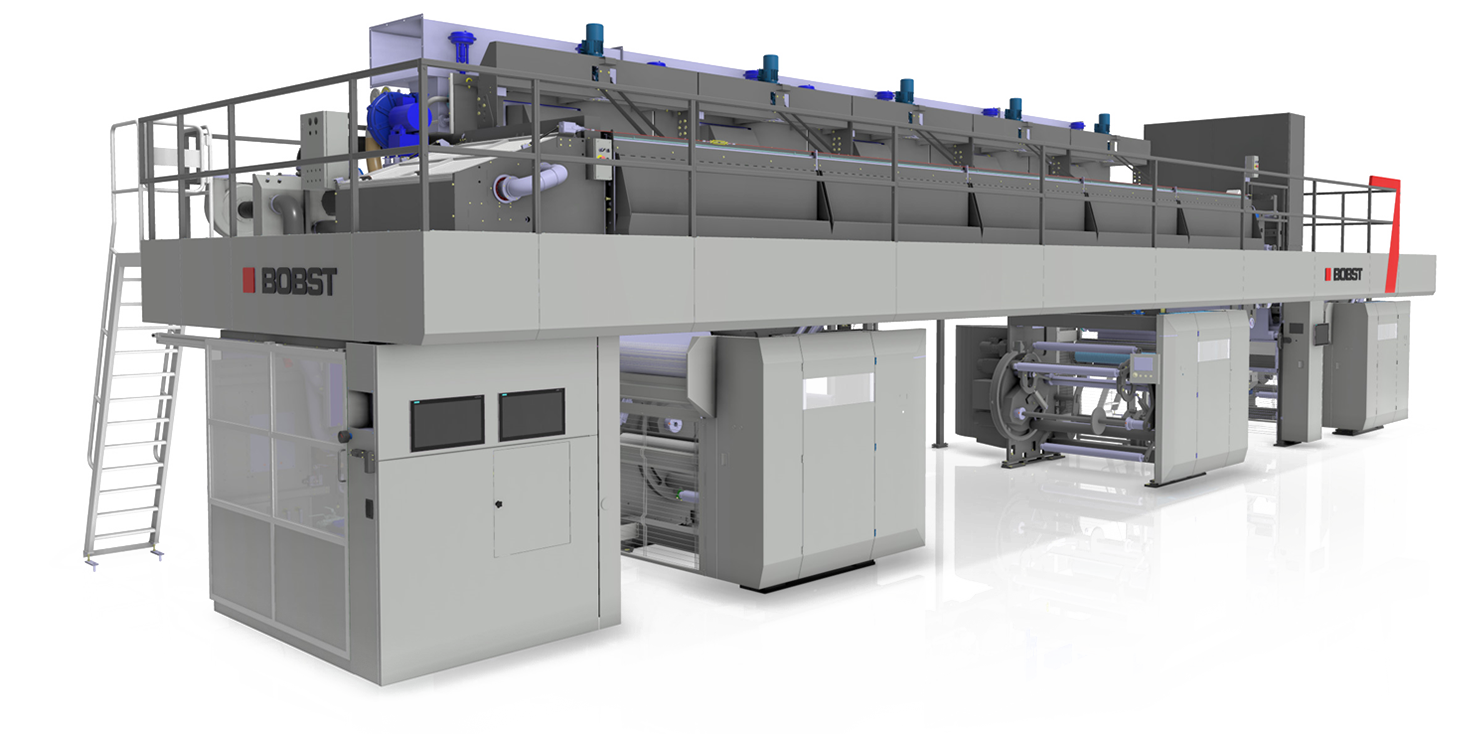

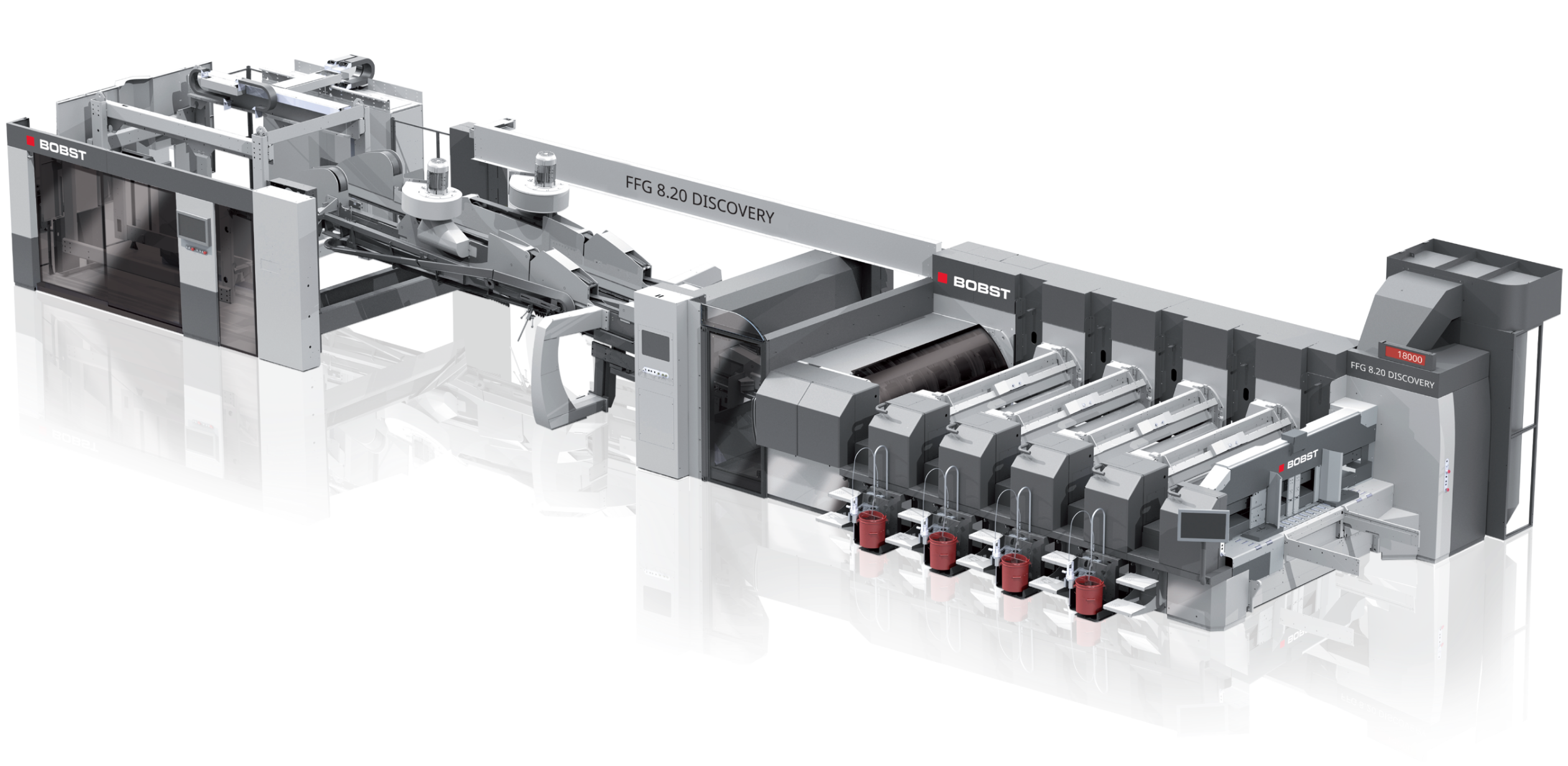

Corrugated board

Boosting end-

to-end efficiency

- Reducing energy consumption by up to 20%

- Maximizing sustainability and cost-efficiency

- Maximizing machine productivity while reducing the overall workload by 90%

- Adding value and widen the range of your applications with minimal adjustments

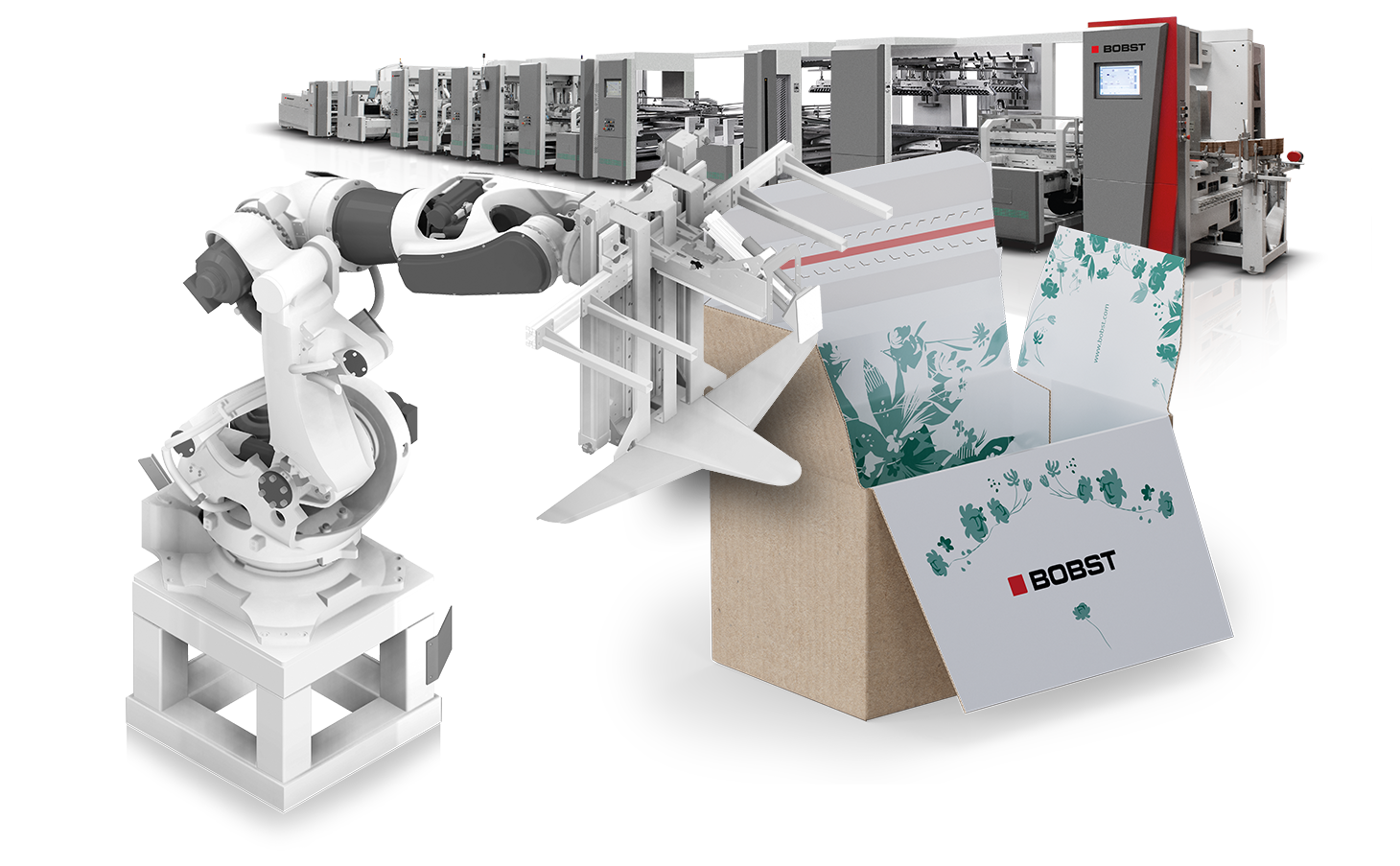

BOBST solutions cover the production of all kind of applications, from the smallest package to the largest.

Our portfolio is completed with automatic peripherals for both upstream and downstream of the lines, based on traditional and even new robotic solution. The performance of our equipment is supported by comprehensive solutions including quality control, services, connectivity and customer support throughout the equipment lifecycle.

BOBST’s offer goes far beyond supplying equipment’s and services. The new technological bricks we are developing in BOBST Connect will enable us to reach a growing number of players in the packaging value chain.

Flexible packaging

Innovating for a

sustainable future

- Increasing the recyclability of your applications to 100%

- Optimizing process control

- Minimizing waste and time

- Increasing productivity and print consistency

- Reducing complexity and downtime of your rotogravure presses by up to 70%

- Boosting your flexibility to meet the ever-changing market trends, by combining two technologies in one machine whilst maintaining premium product quality

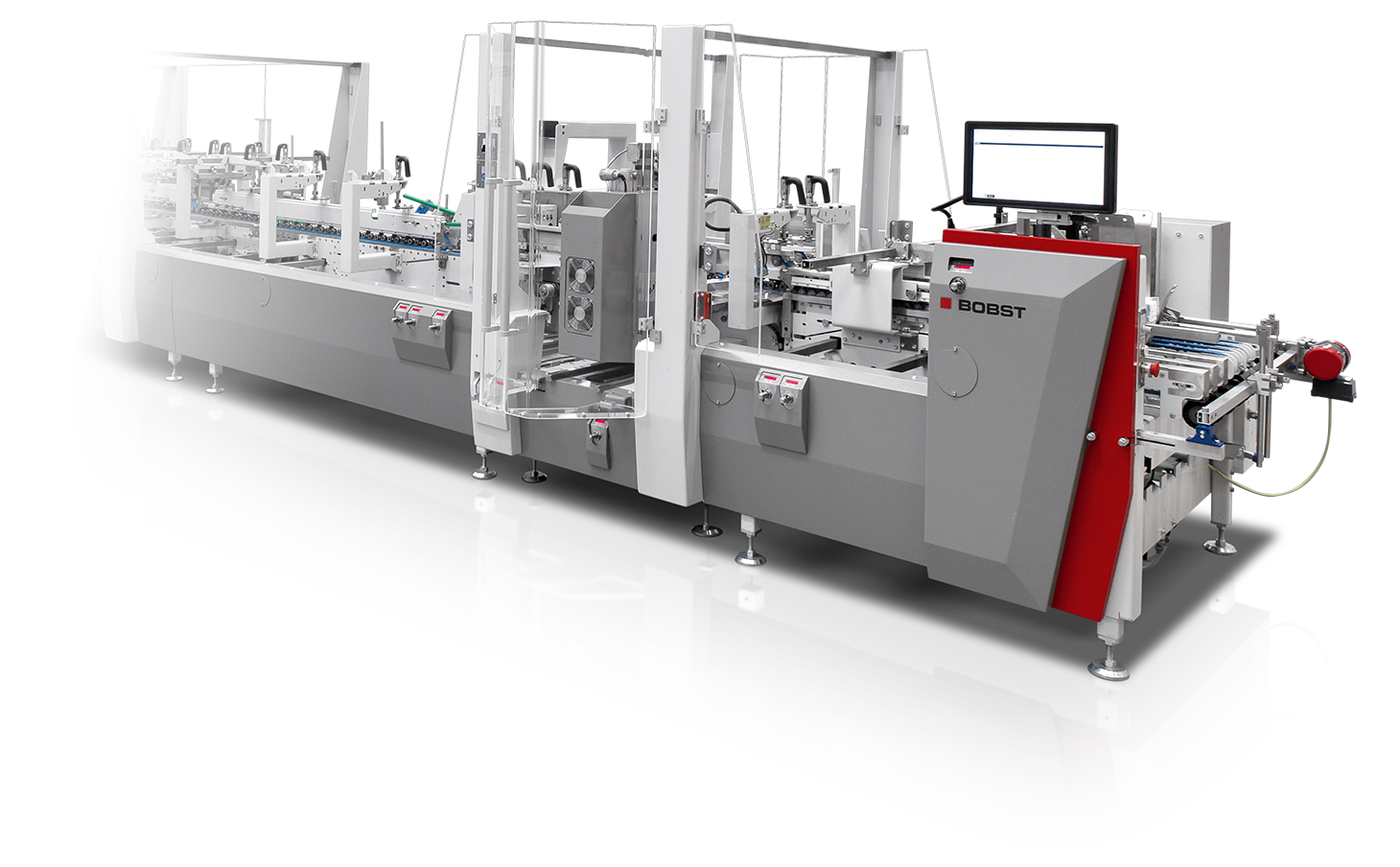

Folding carton

Zero-fault packaging

- Meeting versioning and multilingual requirements by maximizing production flexibility

- Reducing patching by 80%

- Guaranteeing 100% conformity and ensureing zero claim

- Consistent quality

Imagine you can guarantee zero-fault packaging for your entire folding carton production?

BOBST can help customers to achieve zero-fault packaging while powering performance with digitalization & expertise for a sustainable future.

We provide solutions throughout the entire production process – from PDF to finished product. Our solutions give our customers the confidence to push their efficiency to its maximum and ensure perfect results.

value

Compact

Strategy

Empowering

the future

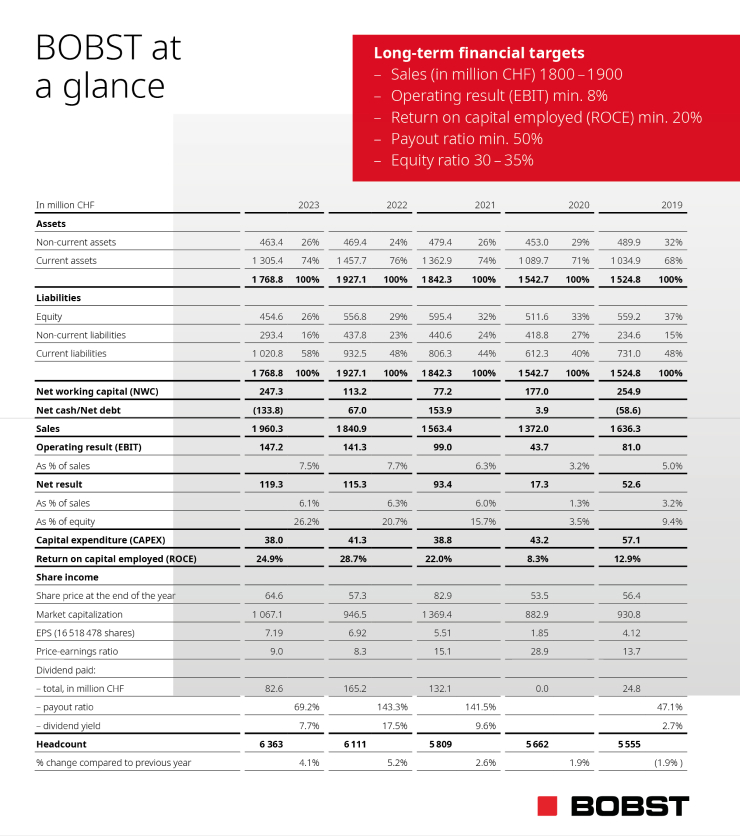

BOBST follows a long-term strategy

We aim to be, or become, No. 1 or 2 in the markets we address to further contribute to the long-term development of the Group. To deliver on these objectives for the label, flexible packaging, folding carton and corrugated board markets, we establish our long-term success on key pillars – innovation, operational excellence, people and growth. We invest in our people, those focused internally to grant operational excellence and those who help our clients maximize their productivity and satisfaction. We build new substrate processing technologies to increase sustainability. We are committed to shaping the future of the packaging world.

Shareholders

We seek to achieve a sustainable profitability ensuring “value creation” for our Group. Our challenge is to be the leading technical innovator in the packaging and label industry, delivering the highest quality and productivity. This will involve developing even stronger relationships with our customers, partners and suppliers, to ensure both a “common good” and a mutual longevity.

Group Executive Committee

Jean-Pascal Bobst

Chief Executive Officer

Attilio Tissi

Chief Financial Officer

Alain Berger

Head of Business Unit Printing & Converting

Raphaël Indermühle

Head of Business Unit Services & Performance

Leading by

values

Values

The phrase that best exemplifies BOBST is “People, Knowledge and Values”. The people of our Group and the vast technical knowledge they have translate into success. The values we aim to hold, both as a Group and as individuals, include Trust, Respect, Passion and Performance. These are the foundation of all collaborations that help us achieve our common goals and sustain our future. With these, we aim to ensure, among other things, a life-work balance, a pleasant work environment and a higher social responsibility.

“People, Knowledge and Values”

are the driving principles of our

company culture.

Sustainable future

BOBST is a family owned company. We aim to strengthen our leadership position, our sustainability for the long-term and we have chosen to invest in digitalization and environmentally friendly packaging solutions. While fulfilling our responsibilities at the local level, we are not only keen to develop the potential of the next generation’s leaders, but also to reveal and encourage the young talents of tomorrow. Transparent management, intergenerational communication that considers the strengths and skills of each one, as well as value creation, are our guiding principles.

perspectives

Jean-Pascal Bobst

Chief Executive Officer

Alain Guttmann

Chairman of the Board

Global impact

Delivering innovation worldwide

- 21 production sites

- Present in > 50 countries

- 11 Packaging Centers:

6 in Europe, 3 in Asia,

2 in the US - > 6 300 employees

Curious for more?